On average, 22 employees in the manufacturing sector die in workplace accidents every year. More than 4,000 sustain injuries that keep them out of the workplace for a week or more. The importance of a thorough manufacturing Health and Safety policy cannot be underestimated.

With this in mind, the Wirehouse team have compiled a complete guide to Health and Safety in manufacturing. Here, you’ll find everything you need to start implementing your Health and Safety procedures and guarantee the wellbeing of your workforce.

Get a professional survey

Health and Safety surveys are crucial to establishing whether your workplace meets the required standards and is a safe place to be. These surveys can be carried out by an internal auditor, and it’s usually good practice to schedule regular checks throughout the year. However, it’s also advisable to utilise a professional service at least once a year.

Employing a professional surveyor is beneficial for two reasons;

- Professional surveyors tend to operate at the forefront of the Health and Safety sector. They understand what the latest workplace issues are and how to mitigate those risks. They know how other businesses operate and where they tend to make mistakes.

- An internal surveyor can be too close to the business. Sometimes a new perspective is required if you’re to identify problems. Problematic work practices can go unnoticed because they’re a part of the established company work culture and things have been done that way for so many years that no one has thought to challenge them.

While training a Health and Safety official to perform internal surveys is recommended, external professional surveyors are necessary, too.

Health and Safety for everyone

The vast majority of workplace accidents are preventable. Typically, they occur when an individual doesn’t understand the risks associated with their actions, they haven’t been provided with sufficient training, or when suitable safety equipment is not provided. This means the most powerful Health and Safety tool at your disposal is training.

Training is much like a suit of armour: if there’s a weak link anywhere in the chainmail it could prove disastrous or potentially deadly. It takes one individual who has not been provided with Health and Safety training to put everyone else at risk. Consequently, every employee on site who is exposed to potentially dangerous equipment, machinery, substances, or work practices needs to be schooled in Health and Safety.

Manufacturing employees should be put through a mandatory induction course that predominantly focuses on Health and Safety. There should also be regular training opportunities, and, after a reasonable period, long-term employees should be made to recap the training and refresh it in their minds.

As an employer, you are responsible for the Health and Safety of your employees. If you put employees in danger by omitting to adequately prepare and train every staff member in safe working practices, you’re not fulfilling your obligations. Health and Safety must be for everyone. It can’t be reserved for those who have direct contact with potentially harmful substances, equipment, or work practices.

Understand the latest developments

Health and Safety law never stands still. Like any industry, the Health and Safety sector is always developing, changing, and adapting to new realities. That’s why you can’t rest on your laurels and presume everything is fine as it is.

Think of it this way. The manufacturing sector is continually having to reinvent, innovate, revolutionise, and improve itself. New technologies and processes are always being introduced. If you’re to keep abreast of the latest manufacturing developments, you’re going to need new Health and Safety policies.

One of the critical ways in which employers can stay up to date is via Health and Safety conferences and events. While general Health and Safety forums can be useful, there are also industry-specific events, which are likely to provide you with a bit more practical insight.

It’s also a good idea to keep in close contact with other organisations in the same industry. Though you’re probably natural competitors, most companies will collaborate to assure the safety of workers operating in potentially difficult circumstances. An industry forum which meets every few months could help businesses share ideas and develop new techniques and processes for keeping their staff safe.

Identify the risks

Risks exist at every stage of the manufacturing process. Since manufacturing employees work in ways that are potentially quite dangerous, we often forget about the risks associated with less dangerous work. Just because an employee is not operating heavy machinery, does not mean that they are not exposed to risk.

Those who work desk jobs in an office are still required to go through Health and Safety training. There are risks and dangers in all workplaces, and a safe and responsible employer will ensure that they’ve systematically identified the dangers inherent in every type of work environment.

Whether you’re talking about your factory-floor employees or back office staff, Health and Safety policies must be drawn up for all workspaces. Though some of your employees may require more rules and regulations, the aim is to make work safe for everyone, not just those most at risk.

In this regard, employers also need to consider how they’re meeting the needs of those who may have slightly different requirements. This could mean pregnant women, disabled employees, or younger employees. A practical Health and Safety policy will consider all employees and all of their needs.

Risk mitigation

Contrary to popular belief, Health and Safety law does not stipulate that employers must remove all risk from the workplace. In reality, this would be impossible. Instead, it states that employers must do what they can to minimise risk as much as is reasonably practicable.

This means that employers are not responsible for predicting every workplace accident. They are only legally responsible for those risks that they could reasonably anticipate and avoid. Granted, this is a lot more difficult in the manufacturing industries, as there are many more risks to consider, but employers are not expected to make the workplace entirely hazard free.

Write a comprehensive Health and Safety policy

Though any business with fewer than five employees doesn’t require a Health and Safety policy, here at Wirehouse we recommend that all businesses draft one. This policy document will detail which individuals are responsible for the various aspects of the Health and Safety in the organisation.

A Health and Safety policy should list the various risks identified in the Health and Safety survey. It should then detail how the company is going to act to mitigate these risks and limit employee exposure to danger. Finally, it will name the individual responsible for ensuring these actions are carried out and for the overall monitoring of that particular aspect of Health and Safety.

Templates for this type of policy document are available online, though it’s also a good idea to talk to a Health and Safety specialist if you require assistance. They’ll be able to walk you through every step of the process and help you create a Health and Safety document that’s tailored to the precise requirements of your particular type of manufacturing.

Consult employees

Health and Safety is not a one-way process. When drafted in the most effective manner, it’s a multi-party dialogue between employer, employees, Health and Safety specialists, and other relevant organisations. As with most things, the broader range of perspectives you gather, the more complete a picture you have.

All manufacturing companies should consult their employees on Health and Safety practices. Primarily, this is because they work on the front line and understand the day-to-day dangers they face better than anyone.

This consultation can occur in many different ways. Employers can have informal conversations with individual employees. They can dedicate a part of the monthly meeting to safety concerns. They can have an anonymous submissions box.

Whichever method you decide to adopt, it’s still essential that you also have an emergency escalation process in place. This a process that can be used by any employee to escalate pressing Health and Safety concerns to a superior. It should be available at all times and be used to address issues that can’t wait until a later time or date.

Think about facilities and equipment

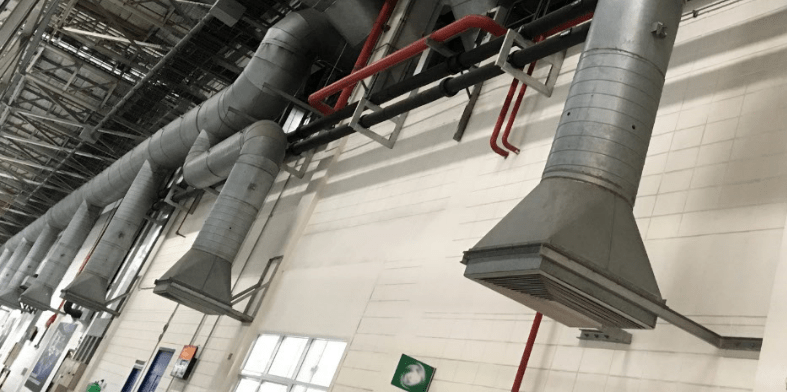

Every type of manufacturing job depends on specialist equipment and facilities. Without this specialist equipment, employees are put in an unreasonable amount of danger, and the work should not be carried out. However, it’s easy to forget about the maintenance of equipment and facilities or to lose information detailing when they should be checked or replaced.

A comprehensive list of safety equipment should be collated and kept safe at all times. This should detail the manufacturer and model, the purchase date, the maintenance date, any information about faults or concerns, and a suggested replacement date.

Likewise, information relating to safety facilities should be kept up to date. This includes welfare facilities, such as toilets and bathrooms, as well as canteens, changing rooms and accommodation.

Recognise the challenges in your particular sector

The manufacturing sector is enormous. In the UK, it employs an estimated 2.5 million workers. It’s also incredibly diverse. Companies can work with cement, ceramics, stone, plastics, textiles and paper. They can work with harmful chemicals, powerful machinery, and extreme temperatures. This diversity makes it difficult to talk about specific risks and dangers.

For employers, the variety of specialisms is one of the most significant challenges. Manufacturing hazards are different for every business and minimising the risks associated with these hazards demands specialist knowledge. The only way you can hope to account for all the potentially dangerous work practices is by pooling information.

If the different parts of the manufacturing industry don’t work together to draft guidelines as to the risks involved in their particular type of manufacturing, the only way we can improve the situation is via trial and error. This is an extremely costly and dangerous method that is unacceptable in this day and age.

If an employer takes a general approach to Health and Safety in manufacturing, they are putting their employees in danger. Health and Safety policies need to be workplace specific, and they need to take the peculiarities of each industry into account.

Work closely with advisory organisations

All manufacturing organisations should use the professional expertise at their disposal, as well as any assistance or guidance offered to them by other organisations. There’s a tremendous amount of professional help available to manufacturers, much of which is easily accessible.

For instance, trade unions are often willing partners when it comes to Health and Safety initiatives. They’re quick to provide information concerning the problems faced by their employees, as well as offering up solutions.

Similarly, professional Health and Safety advisory services and specialist HR organisations (such as Wirehouse) can be of enormous assistance when it comes to identifying risk and moving to minimise it.

The government also offers Health and Safety advice, and there are numerous resources online which can provide you with a more in-depth look at Health and Safety in certain parts of the manufacturing sector. Those employers with the most comprehensive Health and Safety policy – and therefore the safest employees – are typically those that look to the professionals for help and guidance.

What next?

Health and Safety regulations play an integral role in ensuring those working in the manufacturing industry face as little risk as reasonably possible. If employers do not adopt a thorough and detailed approach to formulating a Health and Safety policy, they’re putting their staff at risk and neglecting their legal duty of care. A coherent policy is created by systematically identifying risks to employees, utilising all of the professional assistance at your disposal, and recognising that many hazards are unique to a workplace.