What is Legionella?

Legionellosis is a collective term for diseases caused by legionella bacteria including the most serious, legionnaires’ disease, as well as the similar but less serious conditions of Pontiac fever and Lochgoilhead fever. Legionnaires’ disease is a potentially fatal form of pneumonia and everyone is susceptible to infection. The risk increases with age, but some people are at higher risk, for example:

- People over 45.

- Smokers and heavy drinkers.

- People suffering from chronic respiratory disease (COPD).

- Kidney disease.

- Diabetes.

- Lung and heart disease or

- Anyone with an impaired immune system.

Legionella acquired its name after an outbreak in a hotel in America in 1976 of a then-unknown "mystery disease" which made 221 people sick and caused 34 deaths. The outbreak was first noticed among attendees at a convention of the American Legion – A United States Military Veterans Association. The convention occurred in Philadelphia in July 1976.

This epidemic among U.S. war veterans, occurring in the same city as—and within days of the 200th anniversary of—the signing of the Declaration of Independence, was widely publicized and caused great concern in the United States. In January 1977, the causative agent was identified as a previously unknown bacterium subsequently named Legionella.

Where Legionella Found?

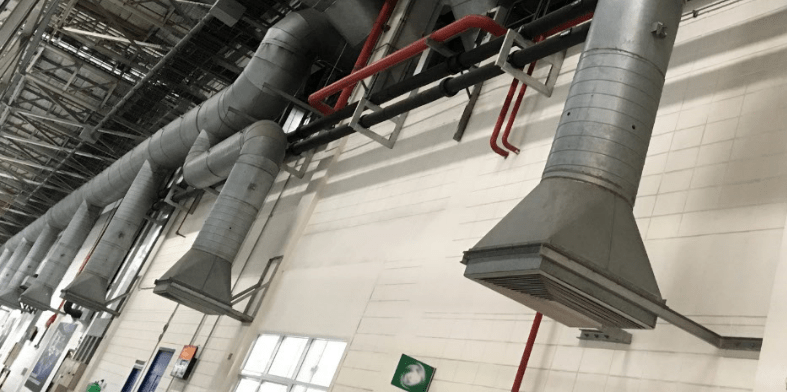

Documented sources include cooling towers, swimming pools, spas and whirlpools, domestic and commercial water systems and showers, ice-making machines, refrigerated cabinets, water features or fountains, dental equipment, soil, automobile windshield washer fluid, industrial coolant, and wastewater treatment plants.

However, whilst legionella bacteria may be found in any of the above examples, which is not to say the bacteria can actively spread and multiply. The conditions of the water, namely the temperature and physical form (spray or droplets) are what have the most significant factors in its ability to harm people.

What are the Symptoms of Legionella?

The symptoms of Legionnaires' disease are similar to the symptoms of the flu:

- High temperature, feverishness and chills.

- Cough.

- Muscle pains.

- Headache and leading on to;

- Pneumonia, very occasionally diarrhoea and signs of mental confusion.

Legionnaires' disease is not known to spread from person to person.

How is Legionella Treated?

The illness is treated with an antibiotic called erythromycin or a similar antibiotic.

Legal Obligations Regarding Legionella

There are approximately 30 pieces of legislation and codes of practice that legionella fall into the category of, but do not worry, we are not going to list them all! Some of the main pieces of legislation are (but not limited to):

- Health and Safety at Work etc Act 1974

- Management of Health and Safety at Work Regulations 1999

- Control of Substances Hazardous to Health Regulations 2002 (COSHH)

- Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 2013

- Health Protection (Notification) Regulations 2010 and in Scotland under the Public Health (Notification of Infectious Diseases) (Scotland) Regulations 1988.

- Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 2013 (RIDDOR)*

* Cases of legionellosis are reportable under RIDDOR if:

- A doctor notifies the employer and

- The employee’s current job involves work on or near cooling systems which are located in the workplace and use water; or work on water service systems located in the workplace which are likely to be a source of contamination.

Approved Code of Practice L8 The Approved Code of Practice: Legionnaires' disease: The control of Legionella bacteria in water systems (L8) contains practical guidance on how to manage and control the risks in your system.

As an employer, or a person in control of the premises, you are responsible for health and safety and need to take the right precautions to reduce the risks of exposure to legionella. You must understand how to:

- Identify and assess sources of risk.

- Manage any risks.

- Prevent or control any risks.

- Keep and maintain the correct records and carry out any other duties you may have.

Temperature Ranges of Legionella:

Temperature affects the survival of Legionella as follows:

- Above 70 °C (158 °F) – Legionella dies almost instantly

- At 60 °C (140 °F) – 90% die in 2 minutes

- At 50 °C (122 °F) – 90% die in 80–124 minutes, depending on strain

- 48 to 50 °C (118 to 122 °F) – can survive but do not multiply

- 32 to 42 °C (90 to 108 °F) – ideal growth range

- 25 to 45 °C (77 to 113 °F) – growth range

- Below 20 °C (68 °F) – can survive, even below freezing, but are dormant

Risk Factors of Legionella

Several factors create a risk of someone acquiring legionellosis, such as:

- The presence of legionella bacteria.

- Conditions suitable for the growth of the organisms, e.g. suitable water temperature (20 °C–45 °C) and deposits that are a source of nutrients for the organism, such as sludge, scale, rust, algae, other organic matter and biofilms.

- A means of creating and spreading breathable droplets, e.g. the aerosol generated by cooling towers, showers or spa pools and

- The presence (and numbers) of people who may be exposed, especially in premises where occupants are particularly vulnerable, e.g. healthcare, residential and nursing homes.

Risk Assessment for Legionella

We recommend for larger and more complex premises, especially those with high-risk individuals who may be exposed to legionella, that you seek the services of a professional third-party water risk assessment company that is accredited. The following list contains some of the factors that are considered, as appropriate, when carrying out the risk assessment:

- The source of system supply water, e.g. whether from a mains supply or not.

- Possible sources of contamination of the supply water in the premises before it reaches the cold-water storage tank, calorifier, cooling tower or any other system using water that may present a risk of exposure to legionella bacteria.

- The normal plant operating characteristics.

- Unusual, but reasonably foreseeable operating conditions, e.g. breakdowns.

- Any means of disinfection in use.

- The review of any current control measures and

- The local environment.

The company appointed to carry out your water risk assessment should also provide you with a schematic drawing of the hot and cold water systems within your premise. This should also indicate the presence of any dead legs.

A dead leg is where a section of piping has been disconnected and capped, for example when a sink or other outlet has been either moved location or removed completely. The remaining section of pipework, if it has not been removed back to the circulating water of the remainder of the water system, will contain water that begins to stagnate and is a breeding ground for the legionella bacteria. All dead legs should be removed or shortened so far as is reasonably practicable.

Do I have to Use a Water Treatment company?

No. This may not be necessary, providing you have the competence, i.e. knowledge and skills to fulfil your health and safety duties, e.g. take responsibility for managing the control scheme.

If you do, you should make reasonable enquiries to satisfy yourself of their competence in the area of work before you enter into any contracts for the treatment, monitoring, and cleaning of the system, and any other aspects of water treatment and control. An illustration of the levels of service to expect from service providers can be found in the Code of Conduct administered by the Legionella Control Association.

An indication of when to review the assessment and what to consider should be recorded. This may result from, e.g.:

- Changes to the water system or its use.

- Changes to the use of the building in which the water system is installed.

- The availability of new information about risks or control measures.

- The results of checks indicating that control measures are no longer effective.

- Changes to key personnel and

- A case of legionnaires’ disease/legionellosis associated with the system.

Control Measures & Risk Mitigation

Cold water systems should be maintained, where possible, at a temperature below 20 °C. Hot water should be stored at least at 60 °C and distributed so that it reaches a temperature of 50 °C (55 °C in healthcare premises) within one minute at the outlets.

For most people, the risk of scalding at this temperature is low. However, the risk assessment should take account of susceptible ‘at risk’ people including young children, people who are disabled or elderly and to those with sensory loss for whom the risk is greater.

Thermostatic Mixing Valves (TMVs) are valves that use a temperature-sensitive element and blend hot and cold water to produce water at a temperature that safeguards against the risk of scalding, typically between 38 °C and 46 °C depending on outlet use.

There is a risk of scalding where the water temperature at the outlet is above 44 °C. In certain facilities with ‘at risk’ patients, this is especially so where there is whole body immersion in baths and showers of vulnerable patients, including the very young, elderly people, and people with disabilities or those with sensory loss who may not be able to recognise high temperatures and respond quickly. Where there are vulnerable individuals and whole-body immersion, testing of outlet temperatures using a thermometer can provide additional reassurance.

The potential scalding risk should be assessed and controlled in the context of the vulnerability of those being cared for. The approach will depend on the needs and capabilities of patients or residents. For most people, the scalding risk is minimal where water is delivered up to 50 °C at hand washbasins and using hot water signs may be considered sufficient, where a TMV is not fitted. However, where vulnerable people are identified and have access to baths or showers and the scalding risk is considered significant, TMV Type 3 (TMV3) is required.

Where the risk assessment considers fitting TMVs appropriate, the strainers or filters should be inspected, cleaned, descaled and disinfected annually or on a frequency defined by the risk assessment, taking account of any manufacturers’ recommendations. To maintain protection against scald risk, TMVs require regular routine maintenance carried out by competent individuals in accordance with the manufacturer’s instructions.

All infrequently used outlets should be flushed on a weekly basis and a record of this kept. This is particularly prevalent in residential care premises, specialised housing, hotels or serviced accommodation following a period of no occupancy. Each tap and water outlet (including showers) should be opened and left to run through for at least five minutes.

The shower should be turned up so it is as hot as possible.

It is important to remember that your hot and cold water temperatures should achieve the following:

- Hot water – a minimum of 50 degrees Celsius after one minute (55 degrees Celsius in healthcare settings). With a TMV fitted, water temperatures at the hot tap should not exceed 44 degrees Celsius.

- Cold water – a maximum of 20 degrees Celsius or below after two minutes.

If you know the water system in a property has not been used for a while, there is a greater chance of higher levels of legionella being present in the system so care needs to be taken.

Since legionella bacteria can be harmful, potentially leading to Legionnaires’ disease when inhaled, it is important to guard against any of the water splashing up towards you or the creation of an aerosol, especially from showers or spray taps.

A monitoring form for this task is available to download from the Guardian General Library.

How Often Should I Test Water for Legionella?

It depends on the system that you have and the outcome of your risk assessment. For open systems, such as cooling towers, evaporative condensers and spa pools etc, routine testing should be carried out at least quarterly. However, there may be circumstances where more frequent sampling may be required.

For hot and cold water systems, which are generally enclosed, i.e. not open to the elements and significant contamination in the same way as cooling towers, microbiological monitoring is not usually required.

There may be circumstances where testing for legionella is necessary e.g. where there is doubt about the efficacy of the control regime or where recommended temperatures or disinfection concentrations are not being consistently achieved.

How Do I Test or Monitor Legionella From My Water System?

Where monitoring for legionella is considered appropriate, the sampling method should be carried out in accordance with BS7592 and the biocide, if used, neutralised where possible.

Water samples should be tested by a UKAS-accredited laboratory that takes part in a water microbiology proficiency testing scheme such as that run by Public Health England. The laboratory should also apply a minimum theoretical mathematical detection limit of <= 100 legionella bacteria per litre of sample for culture-based methods.

What Should I Do If I Receive A Positive Result?

In UK laboratories there are three broad ranges of contamination a water sample tested for Legionella bacteria may show when returned. The figures presented by the lab will be recorded as cfu/l. Cfu stands for colony-forming units, while the lowercase l represents litres.

So, a reading of 150 cfu/l would indicate there were 150 colony-forming units in each litre of water sampled and tested.

The Health and Safety Executive set three legionella trigger or detection thresholds when sampling hot and cold water systems, they are as follows:

Legionella Not Detected or <100 cfu/l

This means the levels of Legionella bacteria detected are below 100 cfu/l or so low as to not show in the test.

However, in hospitals and healthcare environments, the main concern is to protect vulnerable patients, so any detection of legionella should be investigated further. This may call for the system to be resampled to help interpretation of the test results in line with the legionella control strategy and water safety risk assessment.

Legionella Detected >100 cfu/l – <1,000

This refers to levels of bacteria detected at over 100 cfu/l but less than 1,000. This could indicate low level contamination of a water system which would require further investigation. If a minority of samples are positive, the system should be resampled. If similar results are repeated, a review of the control measures and risk assessment should be carried out to identify any remedial actions necessary.

However, if the majority of samples are positive, the water system may be colonised, albeit at a low level. An immediate review of the control measures and legionella risk assessment should be carried out to identify any other remedial action required. Disinfection of the system should also be considered.

Legionella Detected >1,000 cfu/l

This indicates a high level of bacteria whereby immediate remedial action must be taken to prevent a potential outbreak of Legionnaires’ disease. The water system should be resampled and an immediate review of the control measures and legionella risk assessment carried out to identify any remedial actions, including disinfection of the system. Retesting should take place a few days after disinfection and at frequent intervals afterwards until a good level of control is achieved.

If you need advice on Legionella and how to prevent and manage effectively from a health and safety perspective call us on 033 33 215 005 or email websiteenquiries@wirehouse-es.com